Silicon Marine offer an affordable range of single and dual engine exhaust alarms that can be used to monitor wet exhaust systems in boats. Manufactured in the UK, they pride themselves on quality and ease of installation. The unit we are looking at is the SM007B Dual Engine Exhaust Monitor. In our setup, this unit will be used to monitor two Volvo Penta MD32A / Indenor 6.90 Engines from the wheelhouse position.

Table of Contents

Why Is Exhaust Monitoring Important?

Before we begin it’s important to understand why exhaust monitoring is fundamental to the health of an engine. For many years it's been an acceptable practice to simply monitor the engine temperature gauge. If that fails you can then move on to observing visual clues while the engine is running. In most situations, a rising engine temperature will make itself evident, increased heat, sounds, smoke and lastly a loss of compression and power. The problem here is that by the time you've noticed the engine temperature rising, damage can occur. If you use an old-style VDO temperature gauge then this can make monitoring even less efficient.

Before we begin it’s important to understand why exhaust monitoring is fundamental to the health of an engine. For many years it's been an acceptable practice to simply monitor the engine temperature gauge. If that fails you can then move on to observing visual clues while the engine is running. In most situations, a rising engine temperature will make itself evident, increased heat, sounds, smoke and lastly a loss of compression and power. The problem here is that by the time you've noticed the engine temperature rising, damage can occur. If you use an old-style VDO temperature gauge then this can make monitoring even less efficient.

Make no mistake the exhaust system on a motorised boat is just as important as the fuel system that feeds it. You’ll get by without a functioning one for a short while but catastrophic failures will often follow. An exhaust alarm is designed to give you an early warning sign before damage can occur due to the strain that is put on the engine during overheating. The warning will often be auditory and visual, providing your temperature levels have been set right, even the sleepiest of crew will hear it. This will often be an external piezo self-resonating alarm that is triggered by temperature values set by the user.

It is likely that your engine will have a coolant loop and a raw water system. The raw water system is pulled in from an outdrive, or skin fitting from the outside. Most boats will use a raw water strainer. These can become blocked by mud, shells, foul and debris. Just about anything that’s made its way into our ocean is at one stage going to be hovering around your submerged water intakes.

What’s The Worse Case?

If you were driving a clapped out banger in the 90's you may have once neglected to keep the coolant topped up, perhaps you ragged the poor engine silly until it physically parted and lost compression.

When it's a £150 car you bought of your mate's nan it's not such an issue, once the engine cools you hope there's been no damage or you scrap her in and move onto the next victim. When dealing with marine engines you simply can't afford to get it wrong. Head gaskets and engine rebuilds are going to take you out for the season, or worse you'll have to sell up for a loss.

Personally, my Volvo Penta temperature gauges are awful. If you blink the chances are you'll miss a change In temperature or an early warning rise. This is why more boaters over the years have looked at other options of monitoring.

It’s not just the strainer your protecting, there is a multitude of ways in which an exhaust system can fail, from disintegrating water impellers, running engines dry, failing hoses and fittings, seacocks, poorly installed sea strainers, loose strainer caps with missing seals, blocked oil coolers, heat exchangers, holes in coolant tanks, rotten and cracked exhaust manifolds in areas where anodes have failed.

Silicon Marine highlight the importance of monitoring here - “Marine water-cooled exhaust systems are designed to withstand temperatures of up to about 120°C. However, the exhaust gases from the engine may reach in excess of 450°C. In order to protect the exhaust system it needs a continuous flow of cooling water from the engine, should this flow be interrupted by debris being sucked into the intake or by a problem with the water pump or simply forgetting to open the seacock then the exhaust temperature will start to rise immediately. Depending on the extent of the blockage the increased temperature can cause serious damage the exhaust system and water lock. The engine water temperature and/or oil temperature alarms will eventually alert you, however, there can be a considerable time lag especially if the engine has been started from cold which means that damage may already have be done. In order to protect the exhaust components and provide the earliest possible warning, you need to measure the temperature INSIDE the exhaust. Systems which measure the outside temperature will inevitably be delayed as the heat has to make its way through the exhaust components.”

In conclusion, you need to learn to recognise the early indicators by the means of temperature monitoring within your system.

The Full Spec - SM007B - Dual Engine

- Digital Display with histogram.

- Peek temperature hold.

- User-configurable alarm temperatures.

- Internal plus additional external alarms.

- Engine sensors come in 2 x 5-meter lengths and can be supplied longer if required.

- 1.5m display cable, easy to plug into the junction.

- 8 - 28 volt operation.

- A changeable Remote alarm/light option

- Size 8.8 x 6.3 x 2.7cm

- Power consumption - 28mA (no alarm) 80mA alarm sounding)

The Installation

Installing The Display

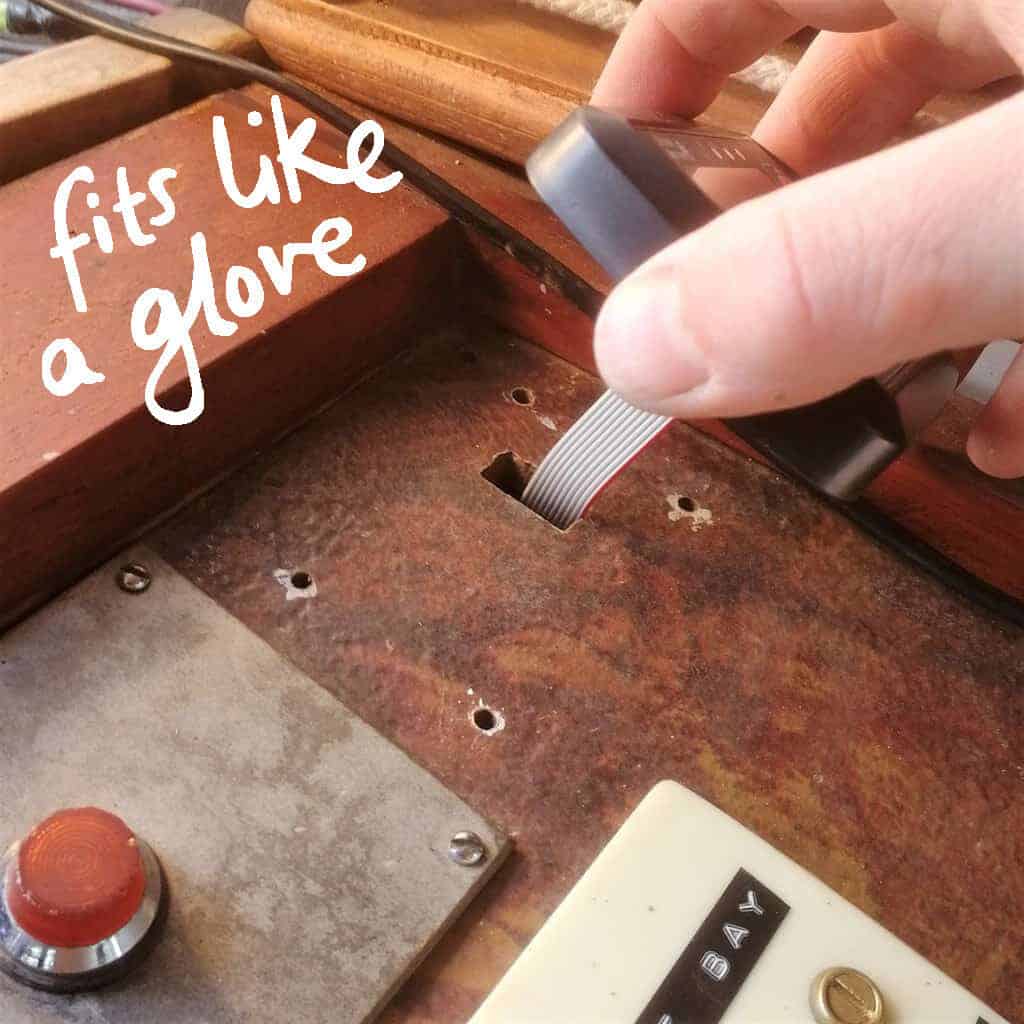

On receiving and opening my kit my initial thoughts were the panel mounted display was a lot smaller than I had expected. However, this didn't directly constitute a negative, in fact, this meant my options for installation were a lot more open.

The panel display is well-built, the unit is sold as waterproof and on inspection looks to be well sealed. The manufacturer recommends that if being installed externally it will require silicone to protect the back of the unit when mounting. My unit would be mounted inside and therefore wouldn't be subject to external conditions aka UV, rain, wind, sea salt and corrosion.

If mounting externally be aware that at current the kit doesn't include a gasket or sealant, my advice would be: use the drill template to make a pattern from thin rubber or neoprene. Cut this with a fresh Stanely or scalpel blade and install it before running the cable.

The display is panel-mounted meaning you will need to cut a small hole for the wiring loom to pass. If you don't own a multi saw then chain drilling will do the job. Once you have your markings pencilled on the surface then you can get to work drilling. You might want to tidy the hole with some sandpaper or a file.

The unit is attached with 4 stainless steel bolts, butterfly nuts and lock washers.

- Make sure you overcut the hole that allows the wiring loom to pass. This will give you some wriggle room.

- Oversize the holes for the bolts so they pass smoothly, even with a drilling template it's best to give yourself room for error.

- you'll need to thread the bolts from the underside once the lock washers and butterfly nuts have been added.

- Don't tighten the butterfly nuts until you are happy that the bolts have been inserted far enough into the panel that they will not strip the thread.

This part was a little tedious for me as the access underneath my control panel is very poor. I lost two bolts to the bilge but once I managed to get two in I was happy with the unit being secure enough for internal mounting. If you were mounting outdoors, you'd want 4 in to create a good even seal with the gasket or sealant.

My dashboard (A work in progress) in the top right-hand corner you can see the dual-engine display. In the settings, the backlight can be adjusted lower and higher. This helps to see the screen better in direct sunlight, in the dark the unit is easily visible however, in direct sunlight you'll have to stand above it to get a clear view. You could improve this with better positioning of the unit.

Granted, the unit is primarily an alarm, the temperature monitoring capabilities are for the occasional glance and this is why perhaps the unit has been designed smaller. The alarm can be tested in the settings and generally heard from any position in smaller crafts.

On a larger boat, with two steering positions, you may make use of a second alarm.

Wiring The Unit

Admittedly, on my way to photograph the kit, I managed to drop all of the paperwork over the side of the boat and straight into the mud. Using myself and my partner's acrobatic skills I was dangled off the side of the boat by my legs and I managed to recover all but 1 sheet of instructions. Unfortunately, this added some time on to the installation. I went onto the Silcon Marine website and downloaded what I thought was the correct wiring diagram however it was the SM007D Dual Engine Exhaust Alarm manual. The unit I installed was the SM007B.

Downloading the wrong instructions meant that when I wired the unit I placed the alarm in the wrong contact. This meant when I later tested the alarm it wouldn't work. Notably, you'll also find the wiring diagram stuck to the inside of the junction box that comes with the kit.

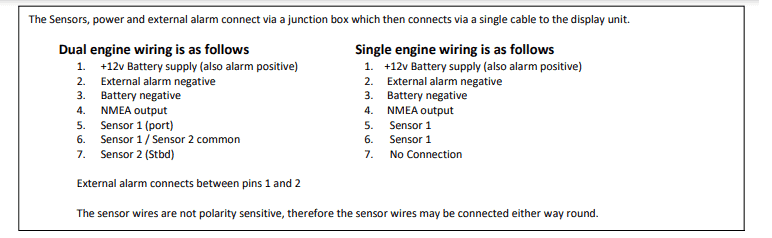

Wiring Diagram For SM007B

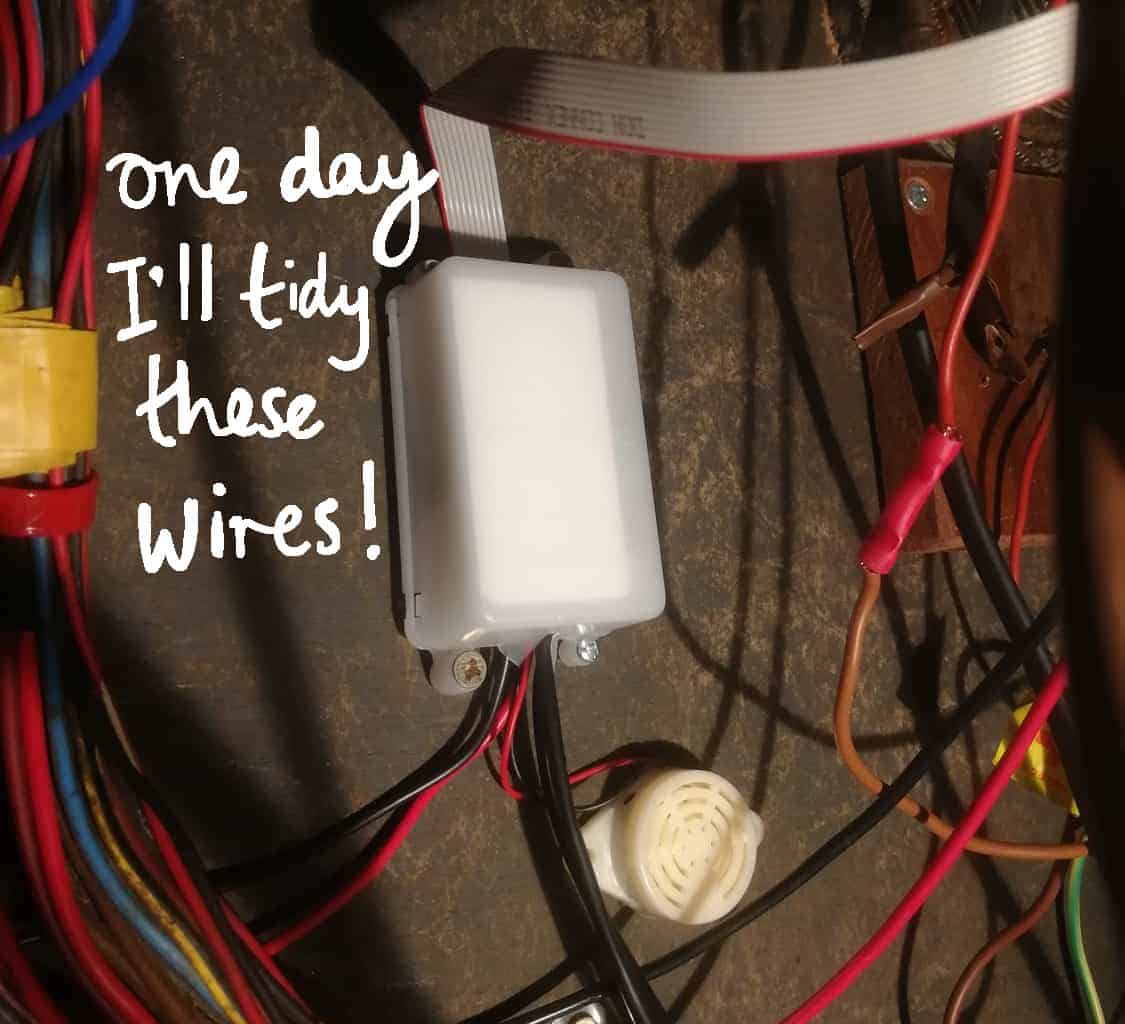

With the right diagram the junction that feeds the panel display is very easy to install. The wires come pre-tinned. All of the junction is enclosed in a plastic box with a self regulated fuse.

Running Wiring Cables

In any equipment installation, running the wires from the unit or this case junction to the engine bay will be the grunt of the work. The access to the original wiring looms on my Seamaster 950 is poor. Meaning to pass wires efficiently I had to chop and create access panels. This is something I've been putting off for a while, it's good practice to be able to access wires if needed but it's a job that's often neglected. Fortunately for me, the idea of having a new shiny toy on the boat is enough drive to get stuck in.

Installing The Sensor Probes

The fitting of the dual sensors was the part of the installation I was least looking forward to. Understandably, the thought of drilling into the wet exhaust hose and somehow making a mistake was on the back of my mind. My exhaust hose happens to be solid rubber with no wiring but to remove and replace you'd need to remove the exhaust elbow. The access to this isn't great. The simple solution here is don't make a mistake.

Speaking to the manufacturer they claim some people prefer to tap into the elbow after the injection point and thread the sensor in. If the engine was out for a rebuild I would consider doing it then. However, on a Volvo Penta MD32A there isn't much room on the elbow after the injection point so the obvious solution was to go for the hose. This is because the suggestion for installation is 150mm downstream of the injection point.

For the novices out there reading, the injection point is the part of the engine where raw water coolant and exhaust gases can mix before exiting the exhaust system.

- Carefully choose a section on the hose where it is possible to squeeze the sensor into the 4mm hole. Too close to other hoses and you may struggle to fit it.

- Cut the stainless steel hose clamps down to the appropriate size, leave them too big and they'll take a lot of effort to tighten. Too short and you'll need a new one.

- As the manufacturer recommends you can cable tie the sensor wire to the clip.

Setting Your Temperature Alarm Threshold

Admittedly I made the mistake of posing this question on the tech forum Recreational Marine Diesel Engine which stirred the hornet's nest somewhat. The opinions on setting a temperature limit vary greatly, from go high to stay low.

We spoke to Tom Salveta - Marine Engineer from the group who said this

"The real answer is there isn't a straight number. The value needs to be derived statistically from the exhaust temperatures recorded while the engines are in operation.

Our Review

The installation was relatively easy to undertake with only a basic set of tools. Each installation will pose its own challenges, depending on the access you have in your engine bay, panel and wiring loom. The unit is solidly built and is quite close to the age-old Nasa clipper display's in the sense that it can take a bit of a beating.

I would personally like a plastic cover to keep the sun off the unit. We are currently making our own cover for the unit from the acrylic canvas. The lack of a power button means you may want to consider wiring a power switch on the dash. Notably, the power consumption is quite low so the choice is yours to make. You may also choose to wire the unit directly into the key ignition.

The sensors are very accurate and highly responsive. In fact, when the engine is not in use the sensors often follow the exact temperature patterns. In my opinion, this is a far superior method of monitoring than the traditional contact sensors. There is a major advantage to having a sensor inside the exhaust system and that is responsiveness. If you are taking a reading from the outside of the engine the downside is, that you have to wait for the heat to conduct through it.

If you have a single engine It's worth considering if you are happy with your current VDO temperature gauge. You can actually use the dual station alarm system to monitor both your exhaust temperature and engine temperature simultaneously. It may take some modification but you can thread the sensor into an existing temperature sensor point. The titles Port and Starboard are changeable in the menu. As you can set individual temperature thresholds for the alarm you can monitor both.

All in all the unit offers an affordable solution to monitoring the health of your exhaust system whether that's single or dual. You're not going to miss the alarm sounding, so providing you've set your temperate limits correctly it's idiot-proof. It's NMEA output is something I will definitely explore in the future but at current is not something I can comment on.

I genuinely love the dual station alarm, and I look forward to seeing the progression of Silicon Marine.

Pros

- An affordable soloution to single and dual engine exhaust alarms.

- Good customer service with a 1-year warranty.

- Self-regulated fuses.

- Low power consumption (28mA (no alarm) 80mA alarm sounding)

- Easily readable screen.

- Foolproof menu settings.

- Individual temperature thresholds.

- Alarm on and off function.

- Installation is fairly easy, providing access is good with proper planning.

- A small easily installable panel mounted display.

- A dual-engine unit can be used to monitor both exhaust and engine temperatures on a single-engine setup.

- Both sensor lead's come as 5 meters as standard and can be extended on request.

- Doesn't require disassembly of the exhaust system to install. Can easily be done in situ with good planning.

Cons

- Could perhaps do with a plastic casing to cover if used externally.

- No off button and will require a switch with additional wiring if needed. (unless you're wiring off the engine ignition key)

Looks like a great addition to the engine gauges. There is nothing nicer than identifying an overheating problem early before the engine high cooling water temperature alarm sounds an alert. Seawater cooling system failures are a common problem, and changing an impeller or unclogging the strainer is never a fun job at sea when the engine is super hot.