We pose the question; if epoxy primers can inhibit rust by forming a barrier then why would we choose to alter its effectiveness by coating over the top of rust-inhibitors?

Table of Contents

The History

Epoxy primers have become the golden standard in boat maintenance worldwide. They were originally marketed as "professional use only" due to the complexities of mix ratios and the hazards associated with applications without adequate PPE. As with all resin-based paint systems, they've evolved to cater for the amateur DIY market. This means their chemical makeup has become safer over time.

Rust Converters come in many forms and brands and their viscosity varies from low-viscosity chemical solutions like Fertan , Jenolite and Flag to high-viscosity paint primers such as Owatrol's CIP.

Some of these converters claim to be compatible with solvent-based paints and 2 part epoxy systems. Unfortunately the information surrounding these claims is vague at best.

We have first hand experience of a commercial paint rep feeding the classic "rust inhibitors are nothing more than snake oil if they were that good we'd sell it!" But how much truth is this argument?

Rust Inhibiting Converters

Owatrol CIP

A rust-inhibiting penetrating primer that has the texture of a thin paint. CIP claims to to be specifically compatible with with epoxy paint systems as well as all 2 part paints.

The Verdict

BRP has put this product to the test above and below the waterline. From twin bilge keel yachts, to entire narrow boats and commerical engine rooms. We even tested it on our works vans without a topcoat. The bright red pigment makes application with a roller incredibly easy. It works incredibly well but it does have one major downfall. It takes weeks to fully set in cold environments. This can really limit workflow as prepping in the same area isn't viable.

Flag Rust Converter

A quick drying water-based and environmentally conscious rust convertor. For interior and exterior use the claims to be over-paintable but doesn't specify epoxy compatibility.

Our Verdict

This is a mid-viscosity paint that stretches really far when hand-rolled. Speaking with the FLAG Rust Converter rep they specify that it is generally only compatible under single-pack solvent-based paints. However, we have personally used it under epoxy primers, with no noticeable negative effects. For single-pack paints it works incredibly fast regardless of weather, It's also well-priced.

Jenolite Rust Converter

No specific claim to offer compatibility with epoxy primers. Their datasheet always recommends testing a paints compatibility before application.

Our Verdict

We have used this converter on engine parts that were painted with a single pack high-temperature enamel. It worked well, It does however set slower than other converters. We haven't used epoxy over this converter so can't comment.

Fertan Rust Converter

Tried, tested and loved throughout the auto and marine industry. Fertan is a tannic acid rust converter. It also has the added benefit of being a water-based and non toxic product.

Unlike other manufacturers, Fertan states that this rust converter can be painted over with 2 pack epoxy systems.

Can You Paint Epoxy Primers Over Rust Converters?

In short yes, you can paint over rust converters with epoxy primers. Despite that, the type of rust converter you use will dictate the maximum bond strength of the epoxy prime coat.

An epoxy coating will only ever be as strong as the surface it's applied to. Any coating you use in-between bare prepped steel will dictate the adhesive bond.

Most rust converter manufacturers don't specify epoxy primer compatibility in their datasheets because this can make a manufacturer liable. This doesn't mean it won't work. The end results however will be weaker. In theory it could also fail if the wrong converter is choosen or the steelwork is not prepped after application. Additionaly, In this day and age there are hundreds of manufactuers of epoxy primers. It's not possible to test all of them with one product.

Try these methods before you commit:

- Run a test patch somewhere inconspicuous, but let the epoxy primer fully set before you the do scratch test.

- Test the converter with a solvent remember there are lots to play with. Turpentine, Acetone, Methyl ethyl ketone, Toluene, Dimethylformamide Mineral spirits, White Spirit, Xylene Glycol ethers. If these don't affect the converter - will an epoxy primer?

- Sand , prep and key your surface but remember you only need to key the surface.

- Compare - Run two test patches. Does the patch with rust converter make a difference?

Why Would You Use A Converter?

Speed is everything when it comes to steel preparation. It's actually, fairly uncommon for your average person preparing a steel boat to be in a completely controlled environment. It's not just salt water and humid conditions a boat painter has to contend with.

Many factors come into play in terms of your optimal painting environment.

- Humidity

- Temperature

- The geographic location, dry dock, marina, hard standing? Salt water, fresh water?

- Wind - carries debris and dust.

The average boat painter won't have an undercover controlled space. Meaning it's highly unlikely that they will be able to prep and stabilise uncoated bare steel fast enough to use an epoxy primer. Furthermore, if you have wet epoxy in a close vicinity to the area you're prepping it will likely end up getting coated in rust particles and debris.

You can break your workflow down into sections, but then you're mixing up batches of 2 part primers. Your rollers, trays, gloves and mixing buckets won't thank you for it!

Time Is Everything When It Comes To Rust Conversion

Now, you can actually mitigate time constraints associated to rust removal by having a boat shot blasted. This can be done with UHP, Soda, Sand, Slurry or even laser rust removal. This will save lots of time in labour but there is one major catch.

In the UK for example, most of these methods are banned in the majority of marinas due to the hazards associated and their impact on the marine environment. In our opinion, dustless blasting is one of the least damaging methods of removing paint. It comes as a surprise to us that the majority of marinas are stuck in their ways and simply wont allow it.

Oh yeah, It's also generally speaking, very damn expensive!

Have Your Boat Blasted If The Options Available.

Now If you are able to have a boat blasted, we recommend you do so. Make sure you have a plan in place to coat it that day. Notably, don't pick a humid day because the boatyard is rushing you.

In this case, an epoxy primer with an added rust inhibitor will be better than an epoxy primer over a rust converter. There are plenty of these rust-hibiting epoxy primers on the market, but we have personally seen the results of Jotmastic 90 and it excels.

We recently saw the results of steel 100-year-old vessel that had spent 10 years in the water between over-coating with only a few working anodes. The Jotmastic 90 held up amazingly well. Only patch sanding and priming was required. The Alu version of Jotmastic 90 works well as an initial coat to inhibit rust.

Using A Rust Inhibiting Epoxy Primer

There is one major pitfall to using a rust-inhibiting epoxy primer without anything underneath it. If your epoxy chips off water can make its way underneath the coating. Water can become trapped under the surface and start to peel the epoxy off. Cured epoxies' rigid and plastic-like state can allow water to seep under large areas. When a steel boat is pulled from the water, if a topcoat has not been used then you may find chips that need repairing. A radius around the repair will also need repairing and patch priming.

Don’t Skip The Prep

You may be fooled into thinking steel won't rust under water as it lacks the key ingredient of oxygen but you'd be wrong. An epoxy coating will effectively seal and prevent rust ingress but only if a surface is prepped properly. Leaving porous flakey rust on a steel surface and skipping the mechanical removal part will trap oxygen and water under the epoxy. This can eventually create pin holes.

Rotary blasters and needle guns are all that's need to remove everything but a light surface rust. Don't think you can use a rust converter to skip the important prep work. It will bite you in the ass.

Our Conclusion

The majority of people painting boats are limited to drills and grinders for the mechanical means of removing rust from steel. This makes a rust converter that is fast to apply and sets in minutes ideal for the majority of jobs. You can simply prep, paint move on. Once the whole area is prepped you can epoxy prime coat the entire area.

However, using a rust converter will affect an epoxies' ability to adhere to a surface but that really boils down to what you're painting and where its going.

If you're painting a boat with epoxy so it'll last for 10 years between paint coats will using a converter make a difference? Probably not. In 3-5 years you'll be taking your boat out of the water regardless to replace anodes anyway, it's unlikely your prime coats will be exposed unless you have severe electrolysis or it simply wasn't applied correctly.

Let’s Go Deeper

To help us understand what forces Epoxy primers come under, let's take a common example.

The UK canal network is incredibly polluted, and it's not uncommon, whilst navigating to find your boat colliding with a plethora of junk below the waterline. Typically you can expect to find, bikes, supermarket shopping trolleys and motorbikes waiting for a boaty victim.

Your paint coating must be capable of standing a 30-tonne narrow boat grinding itself over protruding objects.

Believe us - no paint will win this battle, but an epoxy prime coat will give you the best chance of fighting this. Your chances are increased when you use a bitumen or topcoat that can take some of the impact and reduce the chances of the epoxy chipping.

It seems weird to use an inferior coating but paints don't always have to be well adhered when dealing with below waterline surfaces. Just look at the application of soft anti-foul on yachts and how they're designed to shed over time to protect against underwater growth. Bitumen's topcoats are really a sacrificial coating that's made for taking the brute force of navigation.

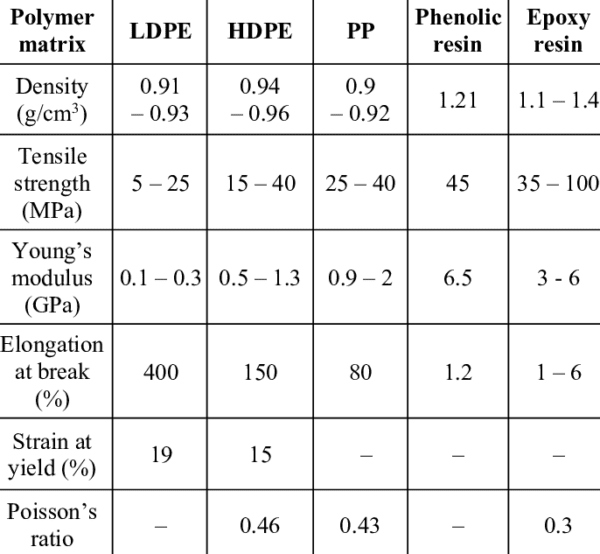

Understanding The Science of Epoxy

Generally speaking, epoxies come under the class of thermosetting polymers made from monomers that contain at least two epoxide groups. If we've lost you there don't worry.

In layman's terms that's a molecule that can be bonded to other identical molecules to form a polymer. To 'makey worky' you need two tins. This is why epoxy paints always need a catalyst to get the party started. If you're reading this having just finished painting your 50-meter Dutch barge with a single tin of epoxy then you might want to think about scuttling your boat at sea- doh!

To understand why painting over a rust converter with an epoxy paint may or may not be a good idea we need to understand epoxy's characteristics.

Bare Steel - Epoxy Adhesion

Epoxy resins can have a sheer strength of upto 41 N/mm² (6000 psi) when applied to bare steel. Notably, the Preparation of the steel will ultimately dictate the overall strength.

It's important to understand the difference between epoxy resins and epoxy paints. An epoxy paint whilst it's a requirement to bond well, doesn't have to take the same loads a structural epoxy adhesive will be exposed to.

Rust converter - epoxy adhesion

A bond to a substrate will always be dictated by the material it's bonded too. If you're using a rust converter then your epoxy primer will no longer be mechanically bonding to bare steel. Instead, it will be bonding chemically to your prepared surface.

We Asked Flag Rust Converter Manufacturer About Their Products Compatability with Epoxy?

"Hey Louis, epoxies have a strong chemical makeup and as a result they can bite into single pack coatings when they temporarily soften after initial application. But the process is not perfect, so most manufacturers always stay on the safe side. Using single pack products as a patch primer and giving it plenty of time to cure before overcoat gives the best results. It's not something we would formally test because of the number of coatings available." - Martin Noon

Write To Us

Do you have a good system for dealing with rust in the marine environment? Got a good recommendation for a rust converter or epoxy?

Please share our articles and help support the BRP platform. Without your support, our articles can't be found. A simple share on your FB profile helps us to reach thousands of new readers.

Hey Lewis thanks for the information. We currently have a dutch barge out of water with a lot of rust preparation work ahead of us. Fertan sounds like a great product so thankyou again!

This is a great dive into the complexities of rust converters and epoxy coatings.

So many articles just scratch the surface and shy away from the difficult bits.

Good job!