Marine sealants are specially formulated to withstand the often harsh conditions of the marine environment where typical DIY home caulk may not suffice. Typically they provide a reliable seal that can prevent water ingress above and below the waterline. They can also be used to effectively block sound and heat transmission as well as preventing dirt and debris accumulation onboard.

Wondering what marine sealants are suitable to use on your boat? It comes as no surprise that it's commonplace for liveaboards to wake up to find rain pouring onto their face from a leaky hatch or window in the middle of the night. Only then will they realise the importance of a quality marine sealant. Before we can begin our journey by picking the right sealant, it's important to know the difference between a sealant and an adhesive sealant.

Table of Contents

Knowing The Difference

An adhesive sealant can be used to seal fittings but also has adhesive properties so it can mechanically bond to certain materials. In short, you could stick your friends bum to a chair using it, but the prank may take up to 24 hours as it can take a long time to cure.

A non-adhesive sealant will generally rely on the aid of a fitting, screw or bolt to create a waterproof seal. With a normal sealant, you are essentially creating a waterproof gasket. You can't rely on normal sealant to hold anything in place; you are relying on a method of fastening, for example; a screw or bolt.

Types Of Marine Sealants

- Silicone

- Butyl

- Hybrids (using the best elements to create better products)

- Polysulphides

- Polyurethane

Silicone

It is said that silicone is an inert synthetic polymer compound and is technically part of the rubber family. You can imagine why its been a favourite in boat maintenance for some time. Its UV resistant, heat resistant, a great insulator and is ideal for creating gaskets. Its downfall is that it makes for a weak adhesive and for this reason sometimes is unpractical for use below the water line.

Hybrid

Hybrids are combinations of the best elements of existent sealers. The idea being that each type of sealant has it's pros and cons so they just pick the pros from the best types. For example the strength of polyurethane with the UV heat resistance of silicone. They will bond better but aren't as strong as polyurethane.

Polyurethane

Polyurethane sealants create an extremely strong mechanical bond when used on the correct surface. They are UV resistant and can be used below the waterline. In the aviation industry on unpressurized aircrafts, windows are sometimes attached using adhesive sealant only. This is a testament to the strength of modern sealants. It's notable that polyurethane is not compatible with acrylic perspex and other types plastic glazing.

Polysulfides

Polysulfides; a synthetic rubber, forms a strong mechanical bond and has an excellent resistance to UV, fuel and oil as well as good general corrosion protection. Polysulfide also makes a great electrical insulator and is resistant to vibration, shock, impact, and thermal changes. It can be easily painted.

Butyl

Butyl is a non-adhesive sealant normally found in the form of tape and has the characteristics of chewing gum, but can now be purchased as sealant. It's great for serviceability and it's easy to remove and re-apply as well as being a lot less messy than traditional sealants. It could last 20 years but it won't look great. It's susceptible to UV damage and can often look like a bit of old chewing gum. It's not suitable for use below the waterline.

We have put together a list of marine sealants followed by some important information to read prior to picking one.

Popular Marine Sealants

Bostik Simson ISR 70-03 - £10 inc shipping - Sealant And Mild Adhesive

ISR 70-03 is a high-grade, one-component, silyl modified polymer marine grade sealant that has been specially formulated for the rough and tumble of industrial environments. It's fast, strong and elastic properties make it ideal for sealing deck equipment. This sealant also adheres to the majority of surfaces used in boat building including aluminium, stainless steel, brass, powder-coated surfaces, galvanised steel, copper, most lacquered surfaces, glass, brass, powder-coated surfaces, zinc, polyester and grp and most impressively Lacquered wood.

ISR 70-03 is a high-grade, one-component, silyl modified polymer marine grade sealant that has been specially formulated for the rough and tumble of industrial environments. It's fast, strong and elastic properties make it ideal for sealing deck equipment. This sealant also adheres to the majority of surfaces used in boat building including aluminium, stainless steel, brass, powder-coated surfaces, galvanised steel, copper, most lacquered surfaces, glass, brass, powder-coated surfaces, zinc, polyester and grp and most impressively Lacquered wood.

- Tensile Strength - 2.6 MPa.

- Elongation Break - 250%

- Strong UV resistance and great ageing properties.

- Solvent, isocyanate and PVC free.

- Resistance to fresh and salt water making it ideal for use below the waterline.

- Fast curing.

- Flexible once set and permanently elasticated within temperatures from –40°C till +120°C.

- Can be painted wet on wet.

- Compatible with the majority of industrial paint coatings.

- Can be sanded after curing.

- Available in white, grey, black, dark grey, brown, yellow.

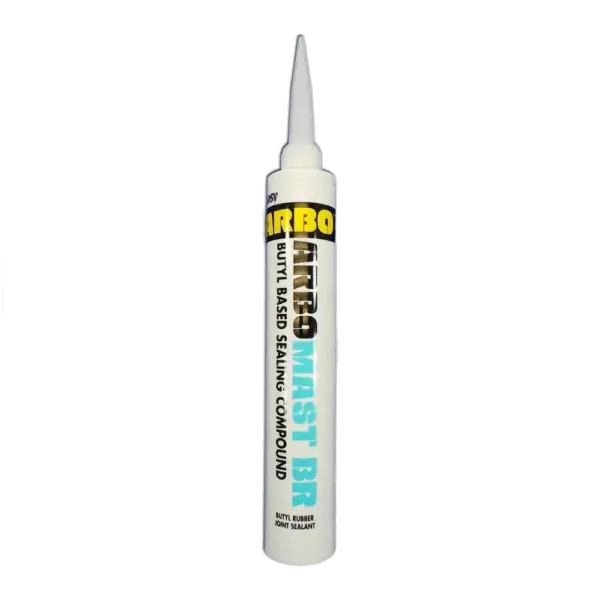

Arbomast BR - £8.00 - Sealant

Arbomast BR is a one component Butyl rubber based sealant that  can be used for bedding deck hardware. It has mild adhesive properties. Sources have claimed it has a proven service life of 20+ years. Like other sealants, it will adhere to most construction materials and substrates. The downside is that it has low UV resistance meaning it isn't suitable for areas exposed to sunlight.

can be used for bedding deck hardware. It has mild adhesive properties. Sources have claimed it has a proven service life of 20+ years. Like other sealants, it will adhere to most construction materials and substrates. The downside is that it has low UV resistance meaning it isn't suitable for areas exposed to sunlight.

- Tensile Strength -Unknown.

- Elongation Break - Unknown.

- 20+ year service life.

- Easy applications.

- Available in grey, teak and black.

Geocel Marine Rubber Silicone - £13 inc shp - Sealant

Geocel is a one-component flexible silicone sealant that has been specifically formulated for a watertight seal which is resistant to the marine environment. It can also mildly adhere to GRP, most metals, glass, painted or varnished wood, and most plastics. It is particularly good for sealing around hatches and port holes, locking nuts and bolts against vibration, insulating electrical connectors, sealing plumbing pipework, creating in-situ gaskets and creating watertight joints throughout.

Geocel is a one-component flexible silicone sealant that has been specifically formulated for a watertight seal which is resistant to the marine environment. It can also mildly adhere to GRP, most metals, glass, painted or varnished wood, and most plastics. It is particularly good for sealing around hatches and port holes, locking nuts and bolts against vibration, insulating electrical connectors, sealing plumbing pipework, creating in-situ gaskets and creating watertight joints throughout.

- Tensile Strength -2.3 MPa.

- Elongation Break - Unknown.

- High flexibility.

- Resistance to salt and fresh water.

- Resistant to high vibrations.

- Available in white, black, clear.

Sikaflex 291i - £13 inc shp - Adhesive Sealant

Sikaflex 291i excels in its mechanical bond strength and is a polyurethane sealant. It will bond with most of the common building materials used in boat construction and maintenance. It will bond to wood, most metals, metal primers and paint coatings (2-C systems), ceramic materials and GRP. However, it isn't suitable for use with plastics that are prone to cracking, for example, acrylic boat windows.

Sikaflex 291i excels in its mechanical bond strength and is a polyurethane sealant. It will bond with most of the common building materials used in boat construction and maintenance. It will bond to wood, most metals, metal primers and paint coatings (2-C systems), ceramic materials and GRP. However, it isn't suitable for use with plastics that are prone to cracking, for example, acrylic boat windows.

- Tensile Strength -1.8 MPa.

- Elongation Break - 500%

- Vibration-resistant.

- Resistant to fresh water, seawater, limewater, sewage effluent, diluted acids and caustic solutions; temporarily resistant to fuels, mineral oils, vegetable and animal fats and oils.

- Not resistant to organic acids, alcohol, concentrated mineral acids and caustic solutions or solvents.

- Available in white, black, brown.

Puraflex 40 - £8.54 inc shp - Adhesive Sealant

Although Puraflex 40 does not claim to be specifically designed for marine use, like Sikaflex its a one component polyethene with excellent mechanical resistance and bonding. Some resellers websites have claimed its use as a marine sealant as well as being backed by user testimonials on various boating forums. It can be used on concrete, wood, metal, aluminium, polyester, glass, uPVC, stone, and ceramics.

Although Puraflex 40 does not claim to be specifically designed for marine use, like Sikaflex its a one component polyethene with excellent mechanical resistance and bonding. Some resellers websites have claimed its use as a marine sealant as well as being backed by user testimonials on various boating forums. It can be used on concrete, wood, metal, aluminium, polyester, glass, uPVC, stone, and ceramics.

- Tensile Strength -1.5 MPa.

- Elongation Break - 700%

- Excellent chemical resistance.

- High mechanical bonding strength.

- Resistance to salt water.

- Available in white, black and grey.

Aquaseal mSEAL 295 - £4.00 inc shp - Mild Adhesive Sealant

mSEAL 295 is one component polyurethane adhesive and sealant that prides itself on its permanent elasticated and vibration resistant properties. It will bond to most marine substrates but is however limited to use for light stress loaded bonding. Notably, it also has a slower curing time and can not be used on surfaces that bleed oils or plasticisers.

mSEAL 295 is one component polyurethane adhesive and sealant that prides itself on its permanent elasticated and vibration resistant properties. It will bond to most marine substrates but is however limited to use for light stress loaded bonding. Notably, it also has a slower curing time and can not be used on surfaces that bleed oils or plasticisers.

- Tensile Strength -1.5 MPa.

- Elongation Break - 600%

- Strong UV resistance.

- Silicone free.

- Resistant to salt water.

- Resistant to high vibrations.

- Outstanding primer adhesion to most marine substrates.

- Excellent adhesion to metals.

- Available in white and black.

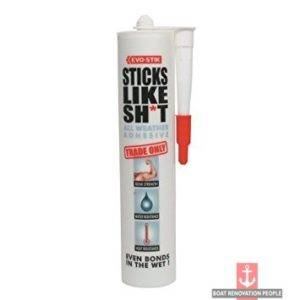

Evo-Stik Sticks Like Sh*t - £5.64 inc shp - Adhesive Sealant

Evo-Stick Sticks Like Sh*it is a high strength single component silyl modified polymer (SMP) based adhesive and can most impressively be applied to damp and even wet surfaces. This makes it a great adhesive sealant to have on board for emergency use. It can be used on a wide range of materials including wood, concrete, glass, brick, ceramics, metals, rigid PVC, plaster, grp insulation boards and foam polystyrene. Notably, it won't bond to polyethene, polypropylene or Teflon.

Evo-Stick Sticks Like Sh*it is a high strength single component silyl modified polymer (SMP) based adhesive and can most impressively be applied to damp and even wet surfaces. This makes it a great adhesive sealant to have on board for emergency use. It can be used on a wide range of materials including wood, concrete, glass, brick, ceramics, metals, rigid PVC, plaster, grp insulation boards and foam polystyrene. Notably, it won't bond to polyethene, polypropylene or Teflon.

- Tensile Strength -1.8 MPa.

- Elongation Break - Unknown.

- Stays elasticated once formed.

- High mechanical bond strength.

- Resistant to water as well as oil & petrol.

- Available in warm white only.

UniBond FlexTec FT101 - £12 inc shp - Adhesive Sealant

UniBond FlexTec FT101 is a one component hybrid polymer which can be used to seal, fill and bond. It claims to be able to bond without the use of a primer to a wide range of materials but doesn't specify which ones it does not. It can also be applied on both damp and wet surfaces but does take 24hours to set and may not ideal for fast same day repairs.

UniBond FlexTec FT101 is a one component hybrid polymer which can be used to seal, fill and bond. It claims to be able to bond without the use of a primer to a wide range of materials but doesn't specify which ones it does not. It can also be applied on both damp and wet surfaces but does take 24hours to set and may not ideal for fast same day repairs.

- Tensile Strength - 1.0 MPa.

- Elongation Break - 400%

- Easy to work with.

- Strong UV resistance.

- Available in white only.

3M 4200FC - £15 inc shp - Adhesive Sealant

3M 4200FC is all around one part polyurethane adhesive sealant that can be used to bond wood, gel coat and fibreglass. It can also be used above and below the waterline.

- Tensile Strength - 1.24 MPa.

- Elongation Break - 400%

- Fast Tack-Free time - 1-2 hours.

- Permanently elastic.

- High vibration and shock resistance.

- Available in white.

Everbuild Stix‐All - £10 inc shp - Adhesive Sealant

Everbuild Stix-All is a one component adhesive sealant utilising the best elements of silicone and polyurethane technologies to create a hybrid. It hasn't been designed for marine use specifically but It is compatible for adhering with most the common materials and can be applied on both damp and wet surfaces. It will bond to metals, plastics, glass, concrete, plasterboard, plaster, polyester, perspex, glass, wood, enamel, painted surfaces and GRP.

Everbuild Stix-All is a one component adhesive sealant utilising the best elements of silicone and polyurethane technologies to create a hybrid. It hasn't been designed for marine use specifically but It is compatible for adhering with most the common materials and can be applied on both damp and wet surfaces. It will bond to metals, plastics, glass, concrete, plasterboard, plaster, polyester, perspex, glass, wood, enamel, painted surfaces and GRP.

-

- Tensile Strength -1.5 MPa.

- Elongation Break - Uknown.

- High bonding strength.

- Resistant to water, petrol, 10% dilute acids/alkalis and most solvents,

- Quick Curing (forms a skin in 10-30 minuets depending on temperature)

- Resistant to temperature extremes ‐40°C to +150°C

- Available in black, brown, crystal clear, grey and white.

CT1 - £10.50 inc shp - Adhesive Sealant

A favourite amongst boating enthusiasts CT1 is suitable as a universal adhesive and will work in all applications. CT1 has no shrinkage and can be applied in both damp and wet conditions. It adheres to most metals (including lead) as well as glass, mirrors, wood, polystyrene and GRP.

A favourite amongst boating enthusiasts CT1 is suitable as a universal adhesive and will work in all applications. CT1 has no shrinkage and can be applied in both damp and wet conditions. It adheres to most metals (including lead) as well as glass, mirrors, wood, polystyrene and GRP.

- Tensile Strength -1.72 MPa.

- Elongation Break - 350%

- Resistant to seawater, aliphatic solvents, oils , greases and diluted organic acids.

- Available in clear, white, black, grey, beige, brown, oak, blue and silver.

3M 5200 - £24 inc shp - Adhesive Sealant

3M 5200 is a one part polyurethane adhesive sealant which reacts chemically with water to deliver an extremely strong mechanical bond. Multiple sources including boat yard workers have claimed it's so strong its use as a marine sealant should be limited. It is apparently too strong for bedding equipment that may need replacing or maintaining in the future. However, It claims it is ideal for seals and joints both above and below the waterline. Debond by Marine Formula can be used to remove the sealant but be warned, it's expensive stuff!

3M 5200 is a one part polyurethane adhesive sealant which reacts chemically with water to deliver an extremely strong mechanical bond. Multiple sources including boat yard workers have claimed it's so strong its use as a marine sealant should be limited. It is apparently too strong for bedding equipment that may need replacing or maintaining in the future. However, It claims it is ideal for seals and joints both above and below the waterline. Debond by Marine Formula can be used to remove the sealant but be warned, it's expensive stuff!

- Tensile Strength -1.72 MPa.

- Elongation Break - 874%

- Great flexibility once set.

- Resistant vibration, swelling or shrinking.

- Available in white.

Sabatack 720 - £13 inc shp - Adhesive Sealant

Sabatack 720 - £13 inc shp - Adhesive Sealant

Sabatack 720 is a one component MS polymer-based adhesive sealant ideal for use in the marine environment. It's primary meant to be used for sealing, seams overlaps and joints with bonding being its secondary function.

- Tensile Strength -2.2 MPa.

- Elongation Break - 300%

- Fast curing.

- Resistant to UV.

- Resistant to high temperatures.

- Avaialble in white, grey and black.

How to tell when it’s time for re-bedding?

Once you own a boat you are trapped in an eternal circle of labour, and whether it's for leisure, living or work purposes you will always need to maintain it. You can limit your workload by using the right method with the right gear. Sealing and re-bedding deck equipment most definitely fall's into the laborious circle but with the right adhesive or sealant and a bit of skill, you can seal your deck with no problems.

Your boat for obvious reasons needs to be tighter than a duck's arse; most importantly below the waterline, but don't disregard your topside leaks. They have the potential given adequate time and rainfall to sink a boat.

Things to look out for -

- Dirt trails - your sealant has failed and is now allowing dirt to collect under your deck equipment. If it's not rust or corrosion then it may be that failing sealant is the cause. If your outer layer has perished then there is a chance that your seal will break next, so it's time to take action.

- Water - visibly dripping through into your cabin during rainy days. Leaking water can often be seen forming small droplets on the bottom of protruding bolt heads. Wait for a forecast of rain or cheat and use a hose to find leaks. If you get your bilge bone dry beforehand, you'll be able to follow the trails of water from any leaky hardware by looking at your bilge areas with a hand torch. This method works amazingly well. If you have a dirty bilge it seems to be even easier and the trail seems to show up clearer where the dirt is wet.

Choosing The Right Sealant

Lots of questions will need to be answered before wasting your money on the wrong kind of marine sealant. Each sealant bonds and reacts with materials in a multitude of ways. Some sealants, for example, will crack perspex boat windows if they are not made from an acrylic compatible chemical. There is nothing more frustrating than bolting and re-bedding all of your boat's windows, only for someone to come along at the end and tell you that you've used the wrong sealant - Doh!

Sealants were originally designed to patch holes in planes during the war but since then they've got a lot more complicated. Corporate competition means companies are continuously trying to outdo each other. The marine industry is constantly screaming out for products that last longer and perform better and subsequently, we are fed increasingly better sealants. A lot of companies who create sealants eventually wise up to the fact that their product will work in the 'marine' industry, and often subtly add it to their datasheet without it being a specific marine product and liable for leisure tax.

Don't worry breaking your requirements into some simple steps really helps.

- Strength - how strong is the mechanical bond strength (some manufacturers give this information)?

- Flexibility - can the sealant move without breaking apart and can it absorb impact?

- Compatibility - will it work with your material you wish to bond it too? Will it be safe for below the waterline?

- Serviceability - how easily will I be able to remove and replace the sealant, how long does it take to set?

- Service life - how long does the manufacturer claim their product lasts and is it UV resistant?

We've even created a beautiful acronym for you to remember: 'SFCSS' (pronounced; Suu-Fuu-Cissss). See, if that's not catchy enough for you then I don't know what is!

Terms Explained

Tensile Strength - the resistance of a material to breaking under tension. To put it even clearer this is the amount of force a material can take until it breaks apart. This is measured in N/mm2 to MPa and can normally be found on a product datasheet.

Elongation Break - Is the % of stretching that the product breaks at. Some sealants have been designed to stretch more than others.

So to summarise, imagine you're an evil man wanting to pull someones' arms off using horses. Tensile strength is the amount of horse's you would need to pull them off which is measured in N/mm2 or MPa. The elongation break is how long the poor persons' arms will stretch before they rip off - ouch!

Thank you for reading! To help keep this website going, please share this article. Any experiences people have had with any of the above products, thoughts or ideas, please feel free to post below!

Reader - Question And Answers

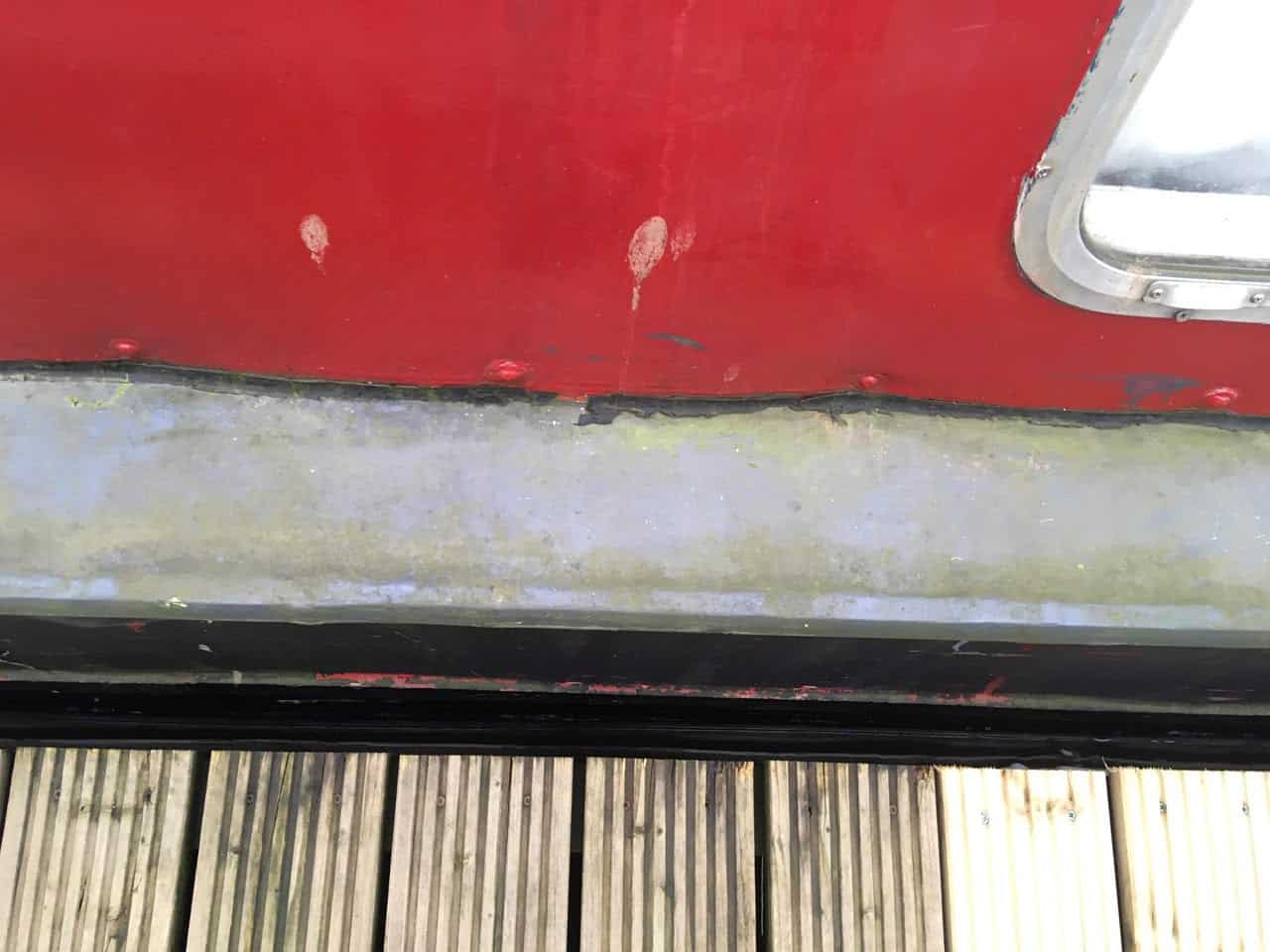

Q1. Renewing Seals Between Gunwales

Tim M - "Hi there, I recently acquired an old narrowboat which I intend to refurbish. The seal between the gunwales and the fibreglass top has rotted away in places (see attached pic) and needs replacing. Some boating forums suggested Sikaflex, Marine Sealant, others recommend Butyl Mastic. Have just read your very comprehensive article on marine sealant, but to be honest it has left me even more confused. your advice on the most suitable product would be greatly appreciated."

Louis - BRP - "Hello Tim, That looks like it could be structural damage caused by someone walking along the deck or delamination. In the photograph, the narrowboat wall looks warped. Can you tell me what your boat is made from on the bottom sides/ the gunwales? Butyl Sealant would be a bad choice for a crack that is going to open and close if the structure is failing. It simply wouldn't work for long, Butyl is not an adhesive sealant, it's essentially used as a gasket on deck fittings, cleats, etc; areas that don't need mechanical adhesion. It's great for this as it has a fairly low elongation limit. In my opinion, you will want an adhesive sealant such as Sikaflex, CT1 or 3M 5200.

To help you understand and make the right choice in the future, just break things down like this; What do I really need? I need a joint that sticks to my substrate, that has some flex, UV resistant, hardy, so the same problem doesn't occur. Is this a one time fix or will I have to do it again? Most sealant companies have a datasheet available from there you can make your choice.

My next question is, can you reinforce that area underneath with support? It's about investigating why this has occurred. As that area will get heavy rainfall it needs to be well sealed.

I hope that's helpful Tim :)"

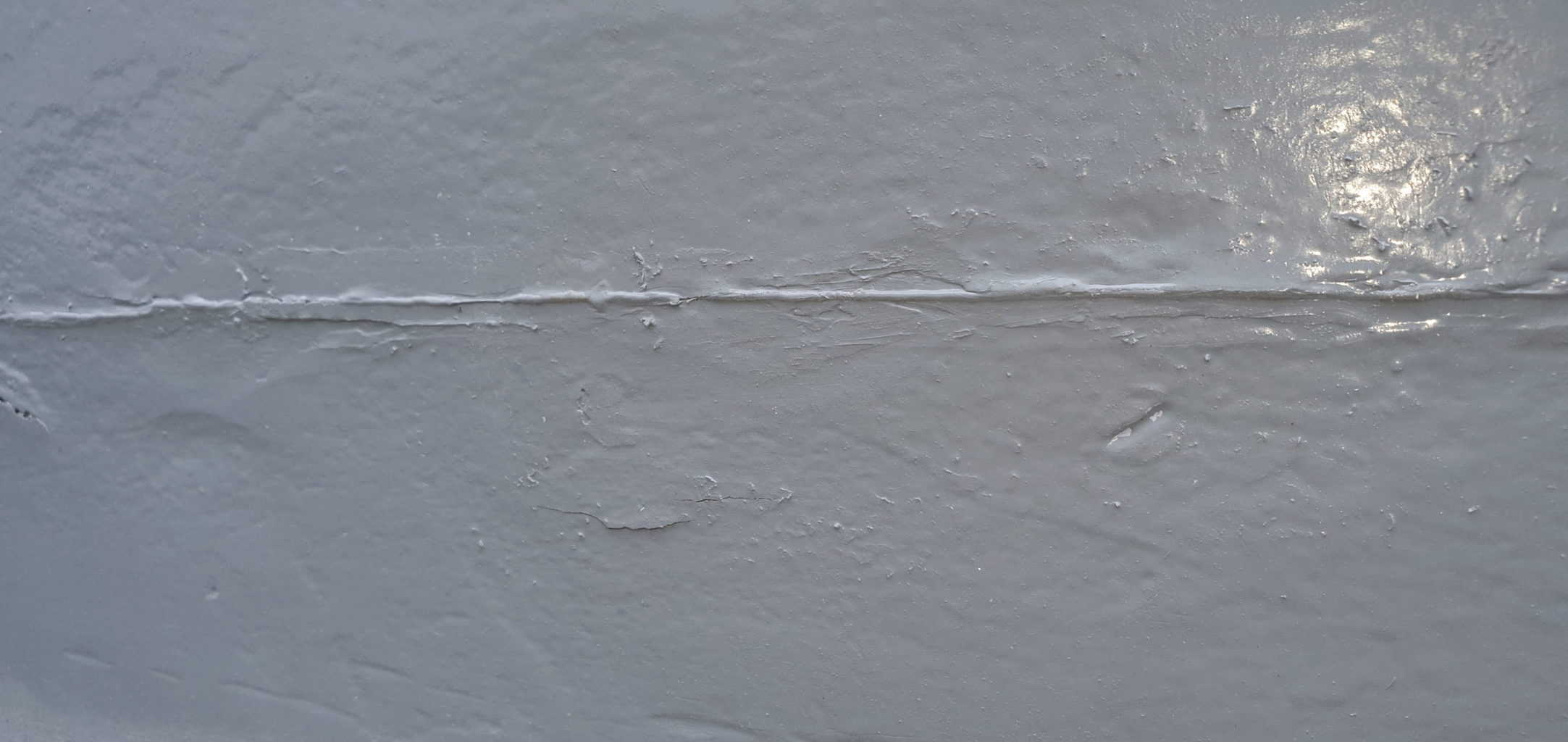

Q2. Renewing A Traditional Putty Caulking

Greg - "Do you have an opinion on renewing traditional putty caulking in an oak hull with something like CT1 or Sudaflex? (I suspect Sikaflex too liquid on a vertical surface). I'm sure the traditionalists will be screaming noooooo! Thanks"

Louis - BRP - "What a good question! Fortunately, I've been in my current boatyard/location long enough to witness 3 owners of the same boat sand back and caulk a hardwood/ possibly teak classic motor cruiser hull. The boat was on the land on hardstanding, each owner would buy the boat, immaculately sand back the hull and caulk.

They started with a car body filler, UPOL a polyester filler which was an awful choice for expanding planks. No flex, no strong adhesion. This dried and cracked out and looked awful. This was later pulled out and replaced with an adhesive sealant StixAll by Everbuild, a hybrid PMS Polymer Sealant.

It looked great for a few weeks but then the planks dried and swelled etc and it popped the sealant. The sealant wasn't to blame here, the problem was there was a great deal of water getting in through the topsides of the boat. Delamination, leaky fittings and windows resulted in water pouring on the inside of the hull like a waterfall. As the boat was out of the water the planks were dry on the outside and taking a hammering of UV but wet on the inside. The new owner renewed the caulking, dropped it in the water and the problem seems to have been solved. I have since borrowed and cruised it and noticed no water ingress now that planks have swollen.

Marine sealants can be used as an alternative to lead putty when used right. This morning I have gone out to photograph a 2nd world war wooden boat that had its seams filled with CT1 just under a year ago (hard standing). It's been exposed to rain, UV and all the elements."

"In the above example, the marine sealant wasn't sanded before being painting. This means it already had existent high spots giving the appearance of bulging. Believe it or not, the CT1 has held in well. What I was seeing from the other boat was cracks where it had failed and fallen out completely."

"Ignore the completely failed paint adhesion from a company that claimed it was a paint designed to specifically bond to oily hardwoods. Check out the seam. this is from the more exposed side one year on. You can see some slight hairline cracks. This could be down to the paint. Given that the boat is out of the water and constantly expanding its survived well.

CT1 is UV resistant, adhesive, and has a high elongation rate of 350% it has a low sag in my opinion and can be used to fill."

Q3. Marine Sealant For Leaky Windows

Greg - "I have a Meridian 391 2010 the front windows are leaking a little bit and is dripping in the master state room on the bed. I have tried to fill the area where the window sits on the lower side with silicon to achieve a water seal. Does not work. Pulled out all the silicon and I am going to try to fill and seal with Butyl or polyurethane. which would you recommend?"

Louis - BRP - "Hey Greg, a professional would tell you that the only way to achieve a good seal is to remove the old windows, take apart the frame, remove the old sealant, degrease and use a bedding compound. This is risky, you can bend the frames, strip the screw heads. You can even put the frames back together with a slight difference and they become too tight to put them back into the cut holes. For this reason, I prefer the workaround.

Remove all of the sealant taking care not to damage the glass or frames, using a sharp knife. Tape the window and frames up using frog tape or blue painters tape then apply the sealant in even smooth beads.

I have used Arbomast Butly sealant to bed the frames where mechanical adhesion is not needed and had excellent results. For the window seams using your method, I would use the Polyurethane. Because you're digging out the sealant and essentially putting it over the joint mechanical adhesion is your best friend. I presume you don't know what compound was used originally? I will add a photograph below of a window frame resealed with Nemesis Mighty Frame & Glazing Sealant with the above method."

The above photo shows a bodge from 3.5 years ago when I first bought A Seamaster 950. I needed to quickly seal the window temporarily at the bottom. You can see I didn't bother to do the existing right-hand side. It's had an onslaught of UV, rain, ice and wind and has subsequently failed somewhat. At the time I thought I'd take apart the frame further down the line (I did not).

"The above photo shows a frame where I prepped the frames properly removing all of the old sealant and degreasing and using the above method. No leaks, other than dirt the seal is in good condition it was leaking prior to this. So to answer your questions, stick to an adhesive sealant, polyurethane oy hybrid polymer with flex and UV resistance."

Sabatack 720 - £13 inc shp - Adhesive Sealant

Sabatack 720 - £13 inc shp - Adhesive Sealant

Great article, its taken out the complicated selection of what to use and where and when to use it. Thanks for taking the time to simplify the sealant mystery.

Thanks Roy – appreciate it !

Great article.

I searched through it and did not find a sealant that is good for sealing acrylic glazing on boats.

Any ideas?

Jon

Hi John , I have heard really good things about Arbomast br which is a butyl sealant, it doesn’t have any adhesive properties but by the sounds of it and the feedback I have heard from others it will seal fittings and windows etc for decades without problems. And if you do ever need to re-apply it’s easy to remove and start again.

Hi Louis, I’ve just read your sealer article, but I’m still unsure which one I should use for sealing around my perspex windows and psinted aluminium window frames.

It requires good adhesion to both surfaces and a degree of flexibility to allow for expansion / contraction in hot and cold weather.

Which one woild you recommend?

Cheers Rich

Hi Rich, If you are using aluminium frames then essentially the sealant will only need to be used to create a gasket. There is my opinion is no need to have a good adhesion if the window is held tight by rivets or bolts and a frame. Aquaseal mSEAL has been known to work well for this purpose and Geocel Marine Rubber Silicone is something I have personally used with good results.

Here is the link to the datasheet for Aquaseal – http://www.everbuild.co.uk/image/data/Tech%20Sealants/mSEAL%20595%20Tech%20Datasheet%20Rev.%202.pdf

Here is the link to the datasheet for Geocel –

http://www.geocel.co.uk/images/uploads/data-sheets-pdfs/geocel-marine-silicone-tds.pdf

The only catch 22 that silicone can also affect aluminium so there are pros and cons to both.

Arbomast BR is also a butyl based sealant that will last for 20 odd years but won’t give you any adhesive properties. I have only tried Geocel so can only recommend that one but I have heard amazing things about Butyl based sealants for perspex.

I want to build a 16′ length X 48″ Beam jon boat out of 1/2″ plywood to use in small protected lakes, powered by 10 hp outboard. Unfortunately I weigh 385 lbs and want to know if 1/2″ marine plywood will be strong enough for me to walk around boat while fishing? I realize the transom will have to be thicker or stronger, to handle extra weight of outboard and force generated wile pushing boat . Which adhesive sealant would be best above and below water line? Most plywood comes in 8 foot lengths so I must bond 2 sheets end to end for bottom can I use same adhesive sealant to glue and seal joint where sheets meet? Please provide recommendations,

I have slight leaking through the deck to hull joint on my 37 year old moody29. I can see the joint and it looks as though the original sealent has gone a bit porus. There is a grouve so I am thinking that I could over fill with a sealent then smooth it down. Do you have a sealent you could recommend and supply. Hull and deck are glass fibre with an aluminium toe rail.

Thanks

I wonder can any of these bond to a Osmo oil used to finish a kitchen counter? A friend recommended 3M Marine Adhesive/sealant but I am not sure it will stick to the wax/oil…will it?

Hi Alex thanks for your question – if we are talking about a table top that has recently been oiled I would personally lightly sand the area that you want to adhere with some 220 grit. Most adeshive sealants will struggle to stick to an oiled surface. Contradictory to this I recently used an old oak table that had been waxed for a worktop. I had to seal and mount a stainless steel sink with bathroom sealant. I forgot about the wax but despite of that it’s still holding strong. Long story short; most things will work it just depends how long you want them to last. Aslong it doesnt compromise safety or structure what have you got to loose. Hope that helps.

Well worth a read. Got great insights and information from your blog. Thanks.

Useful information. Thank you.

I like the helpful info you supply for your articles.

Best of luck with the following!

For acrylic windows, Dow 795 in a thick layer works well. A 30″ foot wide window needs a quarter inch , because acrylic expands and contracts with temperature. There are some Sikaflex and Boatlife products that work as well – check their specs. Thanks for posting the elongation break.

We’re resealing windows on a 1989 47’ Buddy Davis. It’s fiberglass to glass.. old material is removed and area is very clean.. what type sealant do you recommend?

Thank you.

Hello Lee- thanks for getting in touch are you able to explain a little more. When you say you’re resealing – are you trying to bond glass directly to fibreglass with no other mechanical fixtured aka screws or bolts?

I have been going round in circles!!

Which is the best sealant for a Motorhome?

I am sure you know the answer

Many Thanks

I would just like to ask if this page is still in use?

Hope so

In advance

Thanks

Derek.

Hey Derek, it is indeed. I’m dropping some new content this week on dual engine exhaust monitoring- be sure to check it out.

Hi Louis,

I am looking for the best adhesive for my boat

I have an Alaska 500

I belong to a club where we launch off the beach,so we have to attach a 316 steel runner with about 25 ss screws not ideal I know but it’s what works.so I am looking for the strongest adhesive for fibreglass boat hull to 316 steel

Can you help

Thanks derek.

I have a stainless steel rudder stock that has previously been repaired with epoxy putty where it exists the hull . There’s still a small leak in this area.

Which sealant would you recommend. (The repair would been done internally as boat is on half tide mooring.

Thanks

Hey John,

I don’t think I’m fully understanding what it is you need to repair. Surely where the rudder exits the hull there is some kind of shaft and gland?

Would this not normally packed with saltwater grease?

Can you email me over some photos?

Kind Regards

Hey John, Would it be possible to send me some more photos – [email protected]

Hi Louis

Great article – thank you very much

I have a 2001 Searay 480 Sedan Bridge with big 3 piece windshield – bedded in silicone, fixed with retaining screw tabs into a powder coated aluminium frame. From reading numerous forums – everybody has problems with leaking – predominantly at the broken retaining tabs. Some people have used 3M 4200 and 5200, however are revisiting this on an annual basis; exacerbated by rough conditions. I would like try sikaflex 291 (or 291 LOT) or the 3M 4200 due to the Elongation Break of 500 and 400% respectively (I too have ocean going rough conditions – Western Australia). However, your article does not mention bonding to ‘glass’ for either sikaflex or 4200. I am conscious of ‘lack of adhesion to the glass’ but want to counter the possibility of the de-bonding due to load as a result of the ‘broken’ retaining tabs. I have removed the trim to see if the silicone had split or de-bonded from either the glass or the frame. I have a diagram showing cross section of the joint – but couldnt see how to upload. What are your thoughts – you would be a legend among the SeaRay 480 crew if we could find a fix.

Hey Peter,

Sorry for the delayed response.

I’m trying to visualise what it is you’re trying to achieve, I agree that a few photos could definitely help, send them over to [email protected].

You have mentioned screw tab fasteners and silicone, which suggests to me that you are not relying on the mechanical adhesion that those two 3m sealants provide. It is generally said that you would never use any of those products on something that has to be taken apart. Even if your end goal is bedding that lasts forever, like all things in the marine environment it will need to be maintained. Therefore a product with less mechanical bond would be suitable. However, you mention the bond to glass, any good outdoor window sealant should suffice but personally, I’d stick with Sikaflex EBT, or CT1. May I suggest you run a few tests with some glass and find a product you’re happy with? If not I have some CT1 I can run a test with on your behalf.

You’re going about finding a solution the correct way, the datasheet is key. Elongation, breaking points, flex, UV resistance. Let’s find you a solution.

Hi Louis,

Thanks for your reply – very encouraging. I very much appreciated your assistance.

I haven’t yet removed the tape (temporary repair) or the vinyl trim (Taylor Made/SeaRay) to see if the silicone has split or de-bonded from either the glass or the frame.

I will try and do this weekend (weather permitting) and take some photos.

Until I have sent a summary of what information I have so far – including some photos to keep the dialogue going. Thanks again

Hi Louis,

I am looking for the best adhesive for my boat

I have an Alaska 500

I belong to a club where we launch off the beach,so we have to attach a 316 steel runner with about 25 ss screws not ideal I know but it’s what works.so I am looking for the strongest adhesive for fibreglass boat hull to 316 steel

Can you help

Thanks derek.

That’s a good question If you’ve still not found your sealant. I could run some tests on your behalf, how long have you got until you need to complete the work? The datasheets should list all suitable materials but granted in most cases, it’s going to just state “metal”.

If you’ve not found a solution, I’ll have a play, I have some 316 In my workshop. Kind Regards

I have corrosion damage to an aluminum Mercury sterndrive transom plate. The corrosion has expanded a hole that a rubber seawater hose is swaged into. The 1.5 inch diameter rubber hose is a tight fit along the 1 inch long hole in the plate and mechanical swag flares the tube against the plate hole to seal the O.D. Corrosion has produced a 0.60 thou gap around the O.D. of the hose for 1/3rd of the 1 inch hole. I’m looking for a sealant/adhesive to put around the OD of the pipe to seal the gap. The environment is -10C to 40C, slight negative pressure (water pump inlet), salt water. The4 materials to bond to are rubber and painted aluminum. There hose flexes as the sterndrive is steered. The sealant on the outside of the hose would need to be firm enough to resist somewhat the mechanical swage in the I.D. of the hose. Here is a link to a parts catalogue showing the hardware; Items # 15 & 16. Appreciate any help.

https://www.mercruiserparts.com/bam/subassembly/30973/5398/60

Hey Paul,

My first thought , what’s caused the corrosion in the first place, do the anodes need replacing and are there earthing issues with the leg.

I’m trying to visualise the issue, the swaging makes it a little more difficult. I’m not entirely, sure how any tube simply put through and hole will have a good seal. For a gasket to work you really need tension pushing outwards from the ID to seal. rubber changes over time, due to the elements and exposure.

Do you have water ingress? through the shield and into the hull?

If it was me i’d probably get a coded welder patch the hole and have a designated skin fitting with shutoff valve for the inlet.

However, your proposed method could work

ultimately you’ve got to look at what you need to achieve and then check the datasheets.

If you’re bonding rubber to a painted surface then I’d personally i’d use emery paper to remove the paint then your bonding, rubber to aluminium only.

Or you could simply key the surface of the ID.

You need good mechanical adehsion with flex. Look at the datasheet for Sikaflex 291i. You don’t want to use the 3M products as the hose at some point will need replacing.

Let me know what you go with- good luck.

Hi, I am rebuilding my windows on a 54 Hatteras sport fisher. I have dissembled all the glass from the aluminum frames which will be powder coated. What would be your preferred sealant for putting this system back together. The glass fits nicely into the frames so bonding strength doesn’t seem to be the main importance.

Hi I’ve read your article several times and really appreciate the information, we have a fibreglass boat with windows in aluminium frames, we have leaks in several places, so im hoping to be able to dig out the old sealant and re seal the windows. We also have a number of small leaks in the roof (fibre glass) which we need to fill as well as re sealing some of the external fixtures ie hand rails. What sealant would you suggest for the windows? Aluminium to fibreglass? Also could we use the same sealant for resealing the holes made by fixtures? Thanks so much for your help. Regards Sarah

I have a leak from a bowmar aluminium frame deck hatch between the Perspex lens edge and the frame of the hatch. I’ve been advised to dig out the old black sealant and use Sikaflex 291i marine adhesive sealant. Is this correct and will it work? Thanks

Pingback:Situs Slot Gacor

Pingback: link Slot gacor

Pingback: Gacor Slots

Pingback: Slot Online 2023

Wow. Amazing article. Beautifully written and well explained. One of my friends is looking for marine sealants for his boat or an RV roof sealant. I will share your article with him. Thank you so much for providing good information. Keep posting. Good luck.