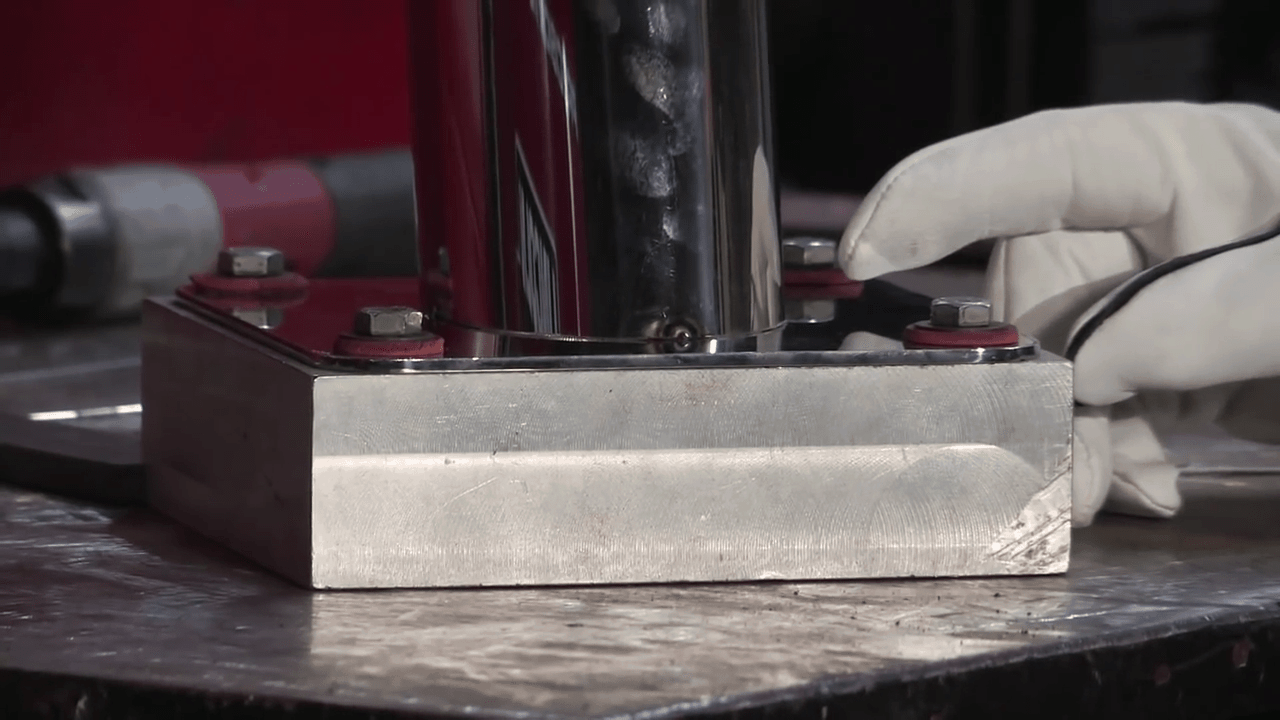

In this video, Carl shows us how to weld corrosion resistant 316 marine grade stainless steel using professional water cooled arch welding equipment. Notably, Carl also uses 316 filler metal to maintain marine grade stainless steel throughout. Bolting the stainless steel to an aluminium block helps to suck the heat away from the weld. Carl claims it is 60% as effective as copper for directing the heat that is created from welding. Being bolted to the aluminium also serves to keep the stainless steel flat preventing it from warping during heating. By keeping a close arch length and heat input down discolouration is prevented on the stainless steel. As always safety when welding is highly important, a welding hood, safety goggles, and a long sleeve flame retardant shirt is a must.

Thank for the great video, make me clear on this since i’m new to welding.