Antifoul; what is it? Why do we need it and how do we go about applying it?

Anti-fouling paints have come a long way and are more widely available than ever. Modern paints work by releasing a controlled amount of biocides over a period of time. Antifoul prevents organisms and plant life from gripping the hull of a boat by releasing chemicals. Some antifoul paints offer protection against underwater corrosion on metal hulls and fittings, although this is not antifoul’s primary use. Essentially antifoul is a protective underwater paint that is designed to slow the growth of sub-aquatic organisms that over a period of time can attach themselves to a hull of a boat. This effect is called fouling (or biofouling) and can be separated into two categories; microfouling and macrofouling.

Microfouling is the build up of bio-organisms such as bacteria, algae, slime etc.

Microfouling is the build up of bio-organisms such as bacteria, algae, slime etc.

Macrofouling is the build up of animals and plant life such as seaweed, sea squirts barnacles, muscles and tube worm.

These organisms can affect a vessel’s performance and durability to move through the water and can often impair or degrade a ship’s hull or mechanical equipment, as a result of the growth and activity of the living organisms.

Table of Contents

A BRIEF HISTORY

The notion of anti-foul on sea-going vessels goes back further than the records themselves. In fact, it’s safe to say that any boat staying in the water for a prolonged period would have visible weeds and strange looking creatures hanging underneath! In the 4th century BC, Aristotle wrote about the suckerfish Remora as the fabled “ship-stopper”. He claimed it slowed down ships as if they were tied to one spot in the ocean. Traditionally, seafarers would scrape their boats with brushes and irons but later records show the use of copper sheathing, wax tar and asphaltum were used instead. It is hard to pinpoint when the anti-foul paint was first used because coating the bottom of boats to seal them used a similar method. It is therefore hard to distinguish what the coatings were for.

During 1571–1862 there was a period in what was called the “Age of Sailing” were international trade and naval war meant the oceans were dominated by sailing ships. This meant that boats would need to be lighter in the water and move faster. With this came for the need for effective methods of protecting boats from build up which slowed them down and so antifoul was born. The speed a boat moved through the water dictated its strength in battle and therefore having a clean bottom became a matter of life or death!

When is time to antifoul

Anti-fouling a boat can be a daunting task especially to those without prior experience. When purchasing a boat, one of the questions that should be high up on the list is “when was it last anti-fouled?” There are many boats for sale that have been sat in the water looking like a woolly mammoth for countless years and incurring potential damage. The problem is that the savvy corner cutting boat salesman will quickly scrape the foul off giving the impression that the boat isn’t in need of an antifoul. It soon grows back and you’re now the owner of a hairy beast. Scraping the antifoul just removes the layers thus making it less effective.

It shouldn’t be a deciding factor on buying a boat but be aware that damage may have been caused via neglect. If the boat hasn’t been anti-fouled then when were the thru-hull fittings and anodes last checked?

Yearly would be an ideal timescale for antifouling although its best to do it as soon as possible if you are unaware of when your boat was last done. Taking a boat out of the water once a year will mean that things will deteriorate a lot slower so the boat will be in a better condition if you ever come to sell it.

Why do I need to antifoul?

The problem is that excessive growth becomes difficult to remove from a boat hull once barnacles have stuck to the fibreglass underneath the antifoul. Corrosion can also occur on metal elements of the boat such as the propellers, sterndrives, rudder, shafts. The majority of marine engines are water cooled and there for require a water intake to cool the engine. If a boat is not anti-fouled, the water intake on the outside of the boat will pull in weed, therefore, blocking the intake and overheating an engine. The same goes for toilet heads which can put yourself into a smelly situation indeed! Fuel consumption will also be increased massively as the boat begins to become heavier in the water.

Putting some effort into anti-fouling will save you money in the long run. If not, the costs will soon catch up with you when problems start occurring with your boat!

Types of Anti-Foul

The chemical composition of antifoul has had many changes over the years due to the effect it has on marine life. In the 1970’s, lead-based antifoul products were replaced by what was thought to of been a much safer option; Tributyltin. It was discovered however that Tributyltin had harmful effects on marine life; changing the sex of sea snails and damaging the immune systems of shellfish. In 2008 Tributyltin antifoul was banned leading the marine sector had to revert to using copper based products. After Tributyltin antifoul was banned, nearly 90% of the industry reverted back to copper. Copper has since been the most popular method of foul prevention. There have been numerous debates about copper and it’s effect on the marine environment however the EU’s Biocidal Products Directive have recently approved the use of copper as an active ingredient.

Hard Anti-Foul

Hard antifouling is often referred to as ‘contact leaching or ‘non-sloughing’ and is nearly always a copper biocide product. It is designed to leach out slowly over a period of time whilst in contact with seawater. A good example of a hard antifoul would be Coppercoat. This consists of a water miscible epoxy resin and 99% pure copper powder (not cuprous oxide). The benefit is that epoxy resin is tough and resistant to the scratching that can occur through grounding, but being water soluble it slowly releases over a long period of time. It’s notable that a standard mix of epoxy and copper powder won’t work however some water-soluble epoxy resins are available and there has been debate over the years about DIY methods of copper coating using soluble epoxy. 1 part antifouls can also be referred to as hard, for example; Hempels Hard Racing. Other types of hard antifoul include Teflon and silicone coatings which work by being too slippery for fouling to stick.

Pros

- Can be scrubbed hard multiple times over a season.

- Ideal for racing yachts that need to be cleaned regularly.

- Can often be rubbed down with fine sandpaper or a Scotchbrite pad dependable on the brand used.

Cons

- The annital outlay is more expensive although it can save money in the long run

Soft Anti-Foul

Soft-anti foul otherwise know as self-polishing, works by constantly releasing biocides whilst it in contact with water. Self-polishing antifoul is most effective when a boat is underway as it is self-cleaning, which in turn replenishes the surface. By using a 1 part antifoul, especially those that can set under water, it is possible to coat a boat in between tides and on slipways depending on your location.

Pros

- Widely available and can be picked up in the majority of marine stores.

- Cheaper initial cost.

- Compatible with most (but not all) existing coatings so you can easily overpaint what is already on the hull, providing all loose and flaking antifioul has been sanded back and patch primed.

Cons

- Will often need to be re-painted more frequently than hard-antifoul.

Location, location

The type of antifoul used is not the only deciding factor in how much overall foul will build up on a boat; the location also plays an important role. Imagine the ocean like a forest constantly changing; new plant life, animals and bugs living and dying daily. As you can imagine, the landscape will be affected over time by its inhabitants. The sea is similar in the way that the ocean and its beds are constantly changing; some years a certain plant or animal will thrive and the next year it won’t. Water temperature, clarity, chemicals, oil spills and even the temperature of the inside of your boat will affect the growth of foul. It is also possible that wherever your boat is moored is too salty for fresh water fouling and to fresh for salt water fouling.

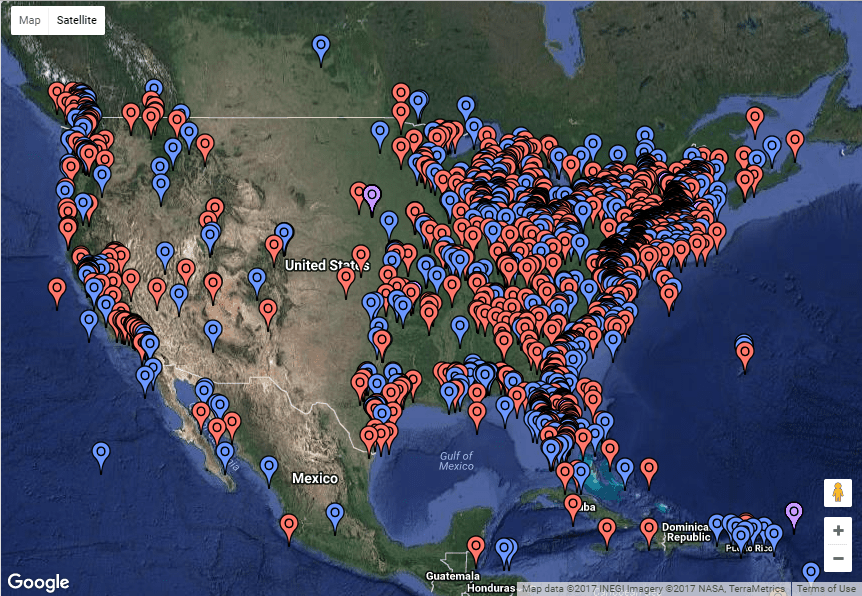

One great way of finding out the best antifoul to use in your area is by asking your neighbouring boats what they used; preferably the clean ones! If that doesn’t work for you then James. Town Distributors have been doing an ongoing survey which asks users to name and rate antifoul usage all around the world.

USING ANTIFOUL IN THE UNITED KINGDOM

We asked the antifoul experts at Seajet and this is what they had to say;

One of the key factors influencing the level of fouling in a particular area is water temperature, where warm water naturally promotes growth and leads to heavier fouling.

One of the key factors influencing the level of fouling in a particular area is water temperature, where warm water naturally promotes growth and leads to heavier fouling.

Water temperature is influenced by (a) the depth of water in that area, (b) the geographical location (eg Scottish waters are generally colder than South Coast areas and (c) what the ambient temperature at any given time/year (ie whether there had been a warm spring and summer that year or not). In the UK, for example, there are distinct differences between the East and the South Coasts. The East is notorious for mud and is peppered with relatively shallow natural harbours, rivers and estuaries where many yacht moorings dry out at low tide. The south coast has generally deeper water locations (apart from various natural harbour locations such as Poole, Chichester and Portsmouth).

How much rainfall in any given year can also contribute to good or bad fouling conditions in any one year. This is particularly true in areas where nitrates (fertilisers) may be washed down into rivers and into the sea, thereby promoting growth in a more rainy season. Other ‘local’ factors, such as whether a yacht’s mooring is in direct sunlight, or remains in the shade for most of its time. Or whether there is steady current movement near to a mooring, or otherwise, can also affect antifoul performance.

HOW TO ANTIFOUL A BOAT

BY seajet

This guide is for Seajet self-polishing antifoul, but is also relevant to many other self-polishing types regardless of brand.

Our general advice to customers is; don’t scrimp on the cost of your antifoul and buy the best available product which you can afford at the time. In the case of ‘self-polishing’ erodable types, the thickness of film coating applied at the outset will have a direct bearing on performance and multi-season protection.

Seajet recommends the following preparation for over-coating existing antifouling in generally good condition:-

- Jet wash the hull and remove any loose or flaking antifoul

- Degrease the hull if required using a suitable boat wash

- Repair any patches with a suitable binder coat or primer, such as Seajet 011 or Seajet 117 multipurpose epoxy primer, for example.

- Once the hull and primer are fully dry, apply your chosen antifoul preferably using a long-haired mohair roller (min 6 inches / 15cm wide), to ensure a thick coat.

- Keep a brush close by for those hard to reach areas

- Ideally, dry film thickness should no less than 100 microns per each coat. In the case of application by brush, more layers may be required to achieve correct film thickness.

- Apply extra coats on the leading edge of the keel and rudder where water friction is strongest and likewise at the the waterline area, where sunlight will increase the potential for growth.

It’s important to check compatibility to ensure that you can safely over-coat the existing anti-fouling that is already on the hull. Teflon based coatings in particular usually need to be removed completely prior to over-coating with a different type of product. If in any doubt, check with the manufacturer before proceeding.

Safety

Seajet advises the following safety and good practice guidelines:-

- Wear protective clothing and glasses or goggles to prevent eye contact and also wear a hat, rubber gloves and a face mask to further protect any exposed areas of skin and protect against dust inhalation.

- Always read the health and safety advice on labels

- Avoid solvents on your skin. Solvent wiping will degrease your skin and can lead to dermatitis.

- Always work in ventilated areas and allow plenty of airflow. Wear a suitable respirator if in doubt

- Always wet-sand antifoul as the dust is toxic

- Do not eat or smoke when handling paint

- Keep cans sealed and dispose of waste paint at a re-cycle centre.

We strongly advise always use a wide, medium ply mohair roller (min 6 inch) which will achieve the correct film thicknesses required. Keeping a brush close by for those hard to reach areas is also recommended.

Try to avoid using the plastic foam type rollers because these tend not to allow enough film coating to be applied per each coat.

If possible, apply antifouling during late morning or early afternoon in calm, dry weather. Try to avoid surface moisture and the on-set of overnight dew, as this may spoil freshly applied antifoul.

Use a high quality ‘out-door’ masking tape around the waterline and to mask off anodes, shafts and fittings etc.

Use plastic sheeting on the ground to keep dust to a minimum or lightly soak the ground with water, once again to keep rising dust to a minimum.

A day or two before using the antifoul keep it at no lower than room temperature. Immediately before applying, warm the paint by standing in a bucket part filled with hot water before application. Warm paint is much easier to apply and gives a smoother finish.

Stir the paint thoroughly with a flat bladed knife before applying. Heavy pigments mean that antifoulings settle easily and constant stirring is important for even consistency coats.

Use vertical and horizontal brush strokes and try to avoid spreading paint out from the centre in a star pattern, as this action means the coatings may not be going on thick enough.

Other brands may differ but Seajet recommends a maximum of six months launch time after application, otherwise, the antifoul can be subject to the affects of bad weather and/or damage whilst a yacht is on the hard-standing. In adverse sunlight, the product may get too dry and start cracking which will seriously affect performance.

If the yacht has been standing for up to 6 months prior to re-immersion then re-application of at least one coat before immersion – more coats if the yacht is to stay in the water for extended periods – is always a good idea.

A special thank you to Seajet for their contributions to this article. In particular Adam from Broad Reach Communications. We at BRP are always open to collaboration with companies that provide useful information to the marine community.

Very interesting. Practical Boat Owner did a good write up on this I found. We are doing quite a bit of research in thus subject at the moment, in preparation for when we start on our yacht Llandoger Trow

Hello Silver, thanks for the feedback, All the information is out there you’ve just gotta get digging, I think the moral is if your getting you boat out once a year for a quick look then you’ll catch the majority of problems before they have time to escalate:D good luck with your project stay in touch.

Thank you for this really helpful guide I hadn’t heard of Seajet Antifoul before but reading their information on application has been really helpful so i’ll be checking them out!

Hello Andrea- Thanks for the feedback good luck with your antifoul journey Ha