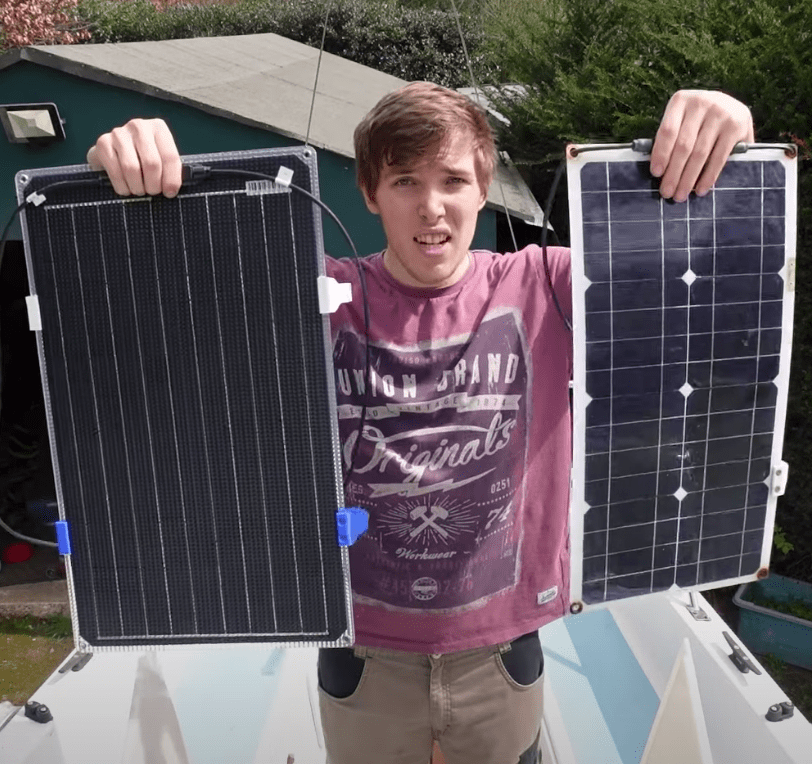

In this video, Alex compares his older 20-watt polycrystalline solar panels with a 30 watt monocrystalline equivalent. He also takes a retrospective look over his custom 3D-printed solar mounts that were used on his previous panels. As always, Alex holds a good standard of 12v electrics and it's clearly demostarted in this video.

Table of Contents

TIPS AND COMMENTS

Solar Range Is Everything

As the team at BRP learnt this year! The ability to adapt and hold an angle on a solar panel is key to harvesting the most power from UK weather. In fact, in the UK the sun's position in the in the sky will massively effective your ability to harvest power. Flat mounted panels rarely produce enough amps to power an onboard system. We love the fact you can easily move the position of the panels to face the Sun on Alex's system.

Consider Your 3D Printing Materials

Generally, it's uncommon to use steel in the marine environment due to its susceptibility to rust. The same principles are applied to 3D printing pieces that are going to be used in the marine environment. Consider the type of plastic that is used in the printing process. Take a look at the original video of Alex manufacturing these mounts Printing 3D Solar Panel Mounts.