Tagged: lightweight, structural beams.

- This topic has 4 replies, 1 voice, and was last updated 4 years ago by

Marc.

Marc.

-

AuthorPosts

-

July 19, 2020 at 8:28 am #6016

Progress! Feeling much better today so did a few bits and bobs on the wagon and headed off down to the boat. I spent a few hours sanding the area the beam will go and got the template made, jury is still out on the material I’ll use for the beam, I’m leaning towards either a traditional laminated hardwood all varnished up and pretty looking; or a laminated ply core with carbon fiber between the panels and around the outside. I’ve got a few posts out on the boat design forums about it and just how strong/stiff it really needs to be. That’s all for today

Attachments:

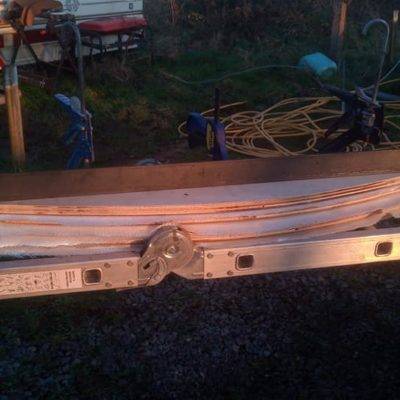

July 19, 2020 at 8:33 am #6020Evening folks, got a decent day in today and thanks to Christopher we got the 5 main sections of the compression spreader beam finished, it took a few attempts to get the template exactly how I wanted it but after that making five copies was relatively painless by roughing out with the jigsaw and trimming to size with the router and a flush cut bit. The woods moisture content is a little high at the moment so they need to dry out for a while before laminating them together.

The final shape to fit will be done when they’re all bonded together.

July 19, 2020 at 8:37 am #6027Evening all 🙂 had a productive day re shaping the main deck beam a touch, I decided it would look nicer and give an extra 30mm of headroom with more of a curve on the bottom.

The iroko for cladding the ply beam and making the dual compression posts has been ordered and I think the darker wood will look fantastic against the white painted bulkhead and fittings.

There’s still quite a lot to do before the main bulkhead goes in, I need to:

Decide how wide to set the posts apart

Cut the old hatch out and put a reinforcement in and laminate it (need the weather to relax a bit for this).

Put the strengthening plates to spread the load from the chain plates and boatlegs across the two new bulkheads.

Build the section that transfers the load from the posts to the keel (this will dictate floor height).

So lots to do in the next few weeks!July 19, 2020 at 8:40 am #6033Evening all, had a marvelous afternoon/evening getting the main deck beam laminated. Not much to report on that front really, heated the epoxy to make it nice and fluid pre coated the wood and laid up a piece of 400gsm bi-axial in between the sections, applied clamps and left it to cure.

Public service announcement: if you need to cut glass mat, get electric scissors. Just do it they’re amazing!

I also spent a bit of time servicing my older and more heavily used power tools, as you can see in the pic the brushes on the router were completely shot, the long one is a new one.

Next on the list is flush cutting the beam and shaping it to fit in the boat, then cladding in the beautiful iroko that’s due early next week.

That’s all for now

July 19, 2020 at 8:44 am #6038Evening folks! Progress has been made… Woop! The main deck beam is in. First the glass under the mast step was tidied up and the gap filled with 10mm G10 then a few sheets of normal fabric with epoxy, the beam was then slathered in finest thickened epoxy and stuck to the hull, all day I’ve been using a extending prop thingy designed for drywall and it chose the moment I was hoisting the beam for final bonding to break, managed to catch the beam without getting covered in resin which was a result and ended up using the old kick it till it wedges in approach with the prop. The beam will be clad in iroko so you won’t see the scruffy plywood so I didn’t really pay much attention to keeping it tidy.

Next up… Deciding where the posts are going, this is a compromise between a small doorway and how far up the hull they sit, the load needs to be carried down to the keel so there will be a bit of trial and error to get something functional and looks good. The posts probably won’t be fitted until I’ve finished with the major parts of the bow as it seems daft to restrict access at this stage. -

AuthorPosts

- You must be logged in to reply to this topic.