- This topic has 2 replies, 1 voice, and was last updated 4 years ago by

Marc.

Marc.

-

AuthorPosts

-

July 19, 2020 at 7:40 am #5986

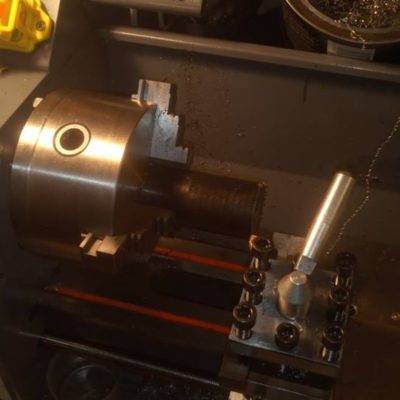

Hurray the new toy has arrived! Going to spend a while getting used to it before committing to the prop shaft but as you can see in the video it chews through 316 stainless without any issues, that was a 1mm cut on carbide insert tools (the smoke is the coolant). The picture is aluminum so if I make a mistake threading it won’t break anything major. Still waiting for the tail stop chuck before I can get on and start making bits for the boat. The first thing will probably be something simple like a spindle pin (316) and rollers (delrin) for the bow roller I made a few weeks ago. Other things on the list are a bronze stuffing box,

bushes for the boat legs,

Cutlass bearing,

propshaft,

Rudder bushings,

6mm thru hull for the motor controller heat exchanger,

New spindle and top swivel for the out of manufacturer roller furler,

And probably all sorts of random bits I haven’t thought of yet!-

This topic was modified 4 years ago by

Marc.

Marc.

Attachments:

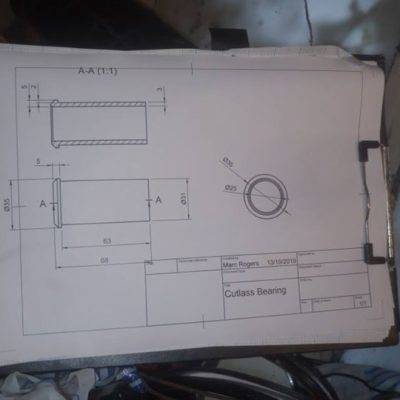

July 19, 2020 at 7:43 am #5989Evening folks, the first actual boat parts are starting to come off the lathe, took me a while to get used to it and still not perfect but this Cutlass bearing should do the job very nicely. I still need to cut groves in to the internal diameter to allow water to lubricate and cool it and haven’t quite figured out how I’m going to do it yet it may just be a case of hand filing them.

The design stages are well underway for the other lathe projects including a hall effect throttle lever for the motor and a phospher bronze stuffing box. I’m really looking forward to making these parts as they’ve been a nightmare to source off the shelf and more major items that can be ticked off the list!

It’s nice to have some inside projects on the table as the area around merganser is currently flooded resulting in the cradle has shifting slightly so all my levels and datum points need resetting before trying to build anything resembling a flat surface! On the plus side all the rain we’ve had only resulted in a few inches of water in the bilge over 5 weeks, given the state of the companion way and that I haven’t sealed the forward hatch yet I’m calling that a win!July 19, 2020 at 8:06 am #6007Boring! I’ve started making the new stern tube adaptor, a 120mm boring bar is pretty much at the limits of the rigidity of the lathe, very light cuts but it did the job and the new adapter for a benatau Cutlass bearing just needs braising on to the existing stern tube.

Attachments:

-

This topic was modified 4 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.